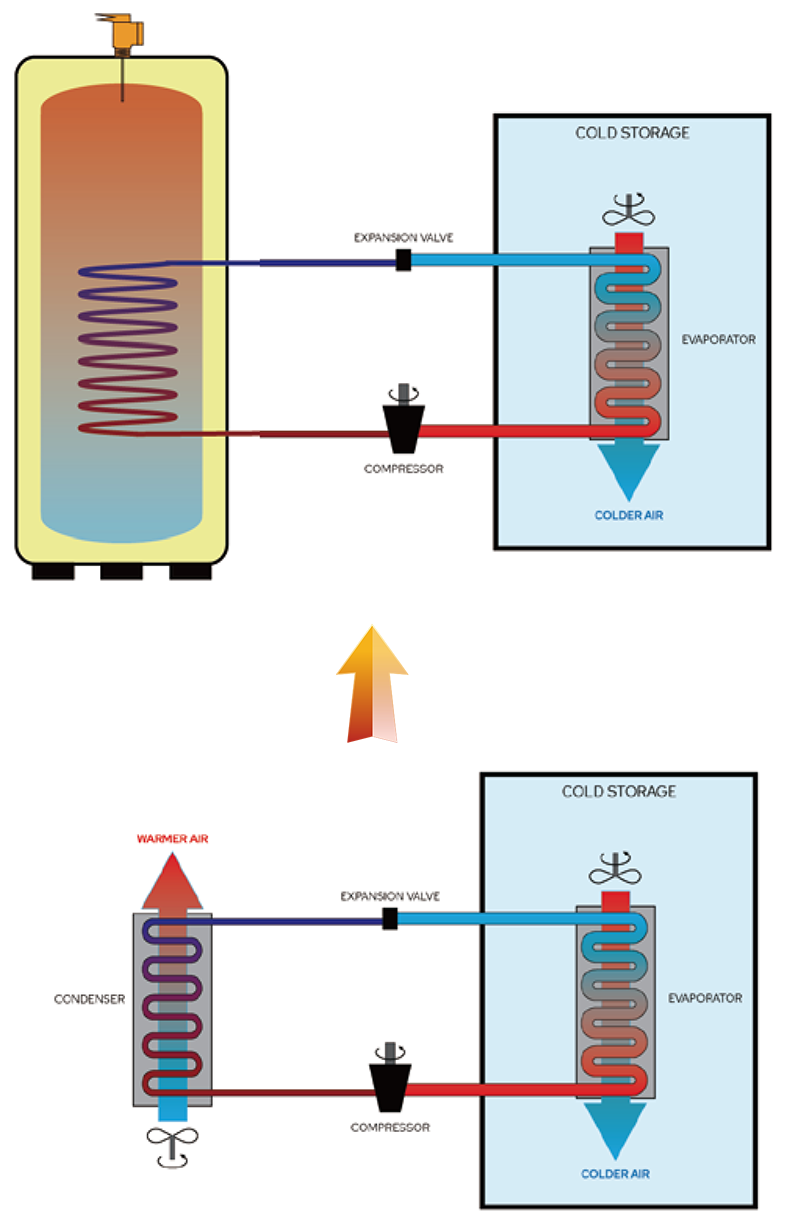

Heat Recovery Tanks are designed for use in cold storage and air conditioning systems, where they capture waste heat generated by refrigeration equipment and reuse it to heat water.

Under normal operating conditions, heat produced by refrigeration systems is released into the surrounding air. By recovering and utilizing this otherwise wasted energy, waste heat recovery tanks convert it into useful hot water, reducing overall energy consumption and lowering greenhouse gas emissions associated with cooling operations. This process improves system efficiency while delivering both environmental benefits and measurable energy savings.

24 Hours Hot Water

Energy Saving

Green House

Customization

High-Pressure Water Supply

| Capacity (L) | 80 100 120 150 200 250 300 400 500 600 700 800 1000 |

| Inner tank material | SUS304 / SUS316L / Duplex Steel 2205 |

| Outer tank material | Galvanized steel with painting SUS201 / SUS304 / SUS316L |

| Insulation thickness (mm) | 50 standard, optional 45/55/60/80/100 |

| Connection size (inch) | 1/2″ 3/4″ 1″ 5/4″ 6/4″ 2″ |

| Electric heater | 1″- 6/4″ 1.5-3Kw 110-240V 50-60Hz |

| Heat exchange material | Stainless steel/TP2 copper |

1. This is a stainless steel, pressurized, insulated water tank with an operating pressure of 6 bar and a test pressure of 10 bar for 10 minutes.

2. This tank can be connected to a variety of heat sources (heat pumps, solar collectors, electric heating, gas boilers, etc.)

Yes. One of the core functions of a heat recovery tank is its ability to store recovered thermal energy for later use . Instead of allowing excess heat to dissipate into the environment, the system transfers this heat into a well-insulated storage tank, where it is retained as hot water.

The tank acts as a thermal buffer , decoupling heat generation from heat demand. This means recovered heat can be collected during periods of continuous equipment operation and then used when hot water is required—even if the original heat source is temporarily inactive. High-performance insulation minimizes standby heat loss, ensuring that stored energy remains available over extended periods.

By storing waste heat, commercial systems gain greater flexibility and stability. Hot water supply becomes more predictable, peak demand can be managed more effectively, and reliance on primary heating sources such as boilers or electric heaters is reduced. This storage capability is particularly valuable in facilities with fluctuating hot water demand or variable operating schedules.

Heat recovery tanks are widely used across a broad range of commercial and light industrial applications , especially where hot water demand is consistent and energy efficiency is a priority.

Common applications include hotels, hospitals, schools, and residential complexes, where recovered heat can be used for domestic hot water supply, laundry operations, cleaning, and sanitation. In restaurants and food service facilities, waste heat recovery supports dishwashing and process water heating while reducing energy consumption.

In commercial HVAC and refrigeration systems, waste heat recovery tanks are often connected to condensers or chillers to capture heat generated during cooling cycles. This recovered heat can then be reused for water preheating or space heating support, improving the overall system coefficient of performance.

Industrial and commercial facilities such as manufacturing plants, data centers, cold storage warehouses, and supermarkets also benefit significantly. In these environments, waste heat recovery tanks help convert continuous operational heat into usable energy, contributing to lower utility costs and improved sustainability performance.

Proper sizing is essential to ensure efficient operation and maximize the benefits of a waste heat recovery system. Tank capacity should be selected based on several key factors.

First, the available waste heat output from the connected equipment must be evaluated. This includes the temperature level, heat volume, and duration of heat generation. Systems that operate continuously or at high load typically justify larger storage capacities.

Second, the hot water demand profile of the facility should be considered. Peak demand, daily consumption patterns, and usage timing all influence optimal tank size. Oversized tanks may increase installation cost and heat loss, while undersized tanks may fail to capture sufficient waste heat.

Third, system integration and space constraints play an important role. Modular or vertically oriented tank designs may be preferred in mechanical rooms with limited footprint, while larger centralized systems may allow for higher-capacity storage.

Finally, future expansion and system flexibility should be considered. Selecting a tank size that allows for growth or integration with additional heat sources—such as heat pumps or solar thermal systems—can provide long-term value.