Boiler Buffer Tanks are engineered to regulate temperature, water volume, and flow within heating, cooling, and domestic hot water systems. Functioning as a thermal “battery,” they store heated or chilled water, releasing it as needed to accommodate fluctuations in system demand and prevent frequent cycling of boilers, pumps, or other heating and cooling equipment.

By stabilizing system operation, buffer tanks enhance overall energy efficiency, reduce mechanical stress and wear on critical components, and extend equipment lifespan. At the same time, they help maintain consistent temperatures, ensuring reliable performance and improved comfort in both residential and commercial applications.

| Capacity (L) | 80 100 120 150 200 250 300 400 500 600 700 800 1000 |

| Inner tank material | SUS304 / SUS316L / Duplex Steel 2205 |

| Outer tank material | Galvanized steel with painting SUS201 / SUS304 / SUS316L |

| Insulation thickness (mm) | 50 standard, optional 45/55/60/80/100 |

| Connection size (inch) | 1/2″ 3/4″ 1″ 5/4″ 6/4″ 2″ |

| Electric heater | 1″- 6/4″ 1.5-3Kw 110-240V 50-60Hz |

| Installation | Vertical / Horizontal / Hanging |

Selecting the correct boiler buffer tank size is essential for achieving optimal performance and efficiency in a home heating or hot water system. A buffer tank functions as a thermal reservoir that increases the system’s water volume to reduce the frequency of short cycling in heat pumps, boilers, or other heat sources. Proper sizing ensures the system runs smoothly and consistently, reducing wear on components and improving energy efficiency.

In practice, buffer tank volume should be matched to the heating capacity of the source and the desired “on-time” for that source. A general guideline often used in hydronic systems is to provide approximately 15 to 50 liters (4–13 gallons) of buffer volume per kilowatt (kW) of heating capacity to balance system operation without unnecessary cycling. Larger tanks store more thermal energy and allow longer run times, which is beneficial for heat pumps that perform better with sustained operation.

Boiler Buffer Tanks can be installed in several orientations— vertical, horizontal, or even hanging —to accommodate installation space constraints and layout preferences within mechanical rooms or utility closets. The flexible installation options make buffer tanks suitable for a variety of household environments, even where space is limited.

Correct installation is critical to system performance and safety:

The tank should be positioned close to the heat source (such as a heat pump or boiler) to minimize heat loss and reduce circulation resistance.

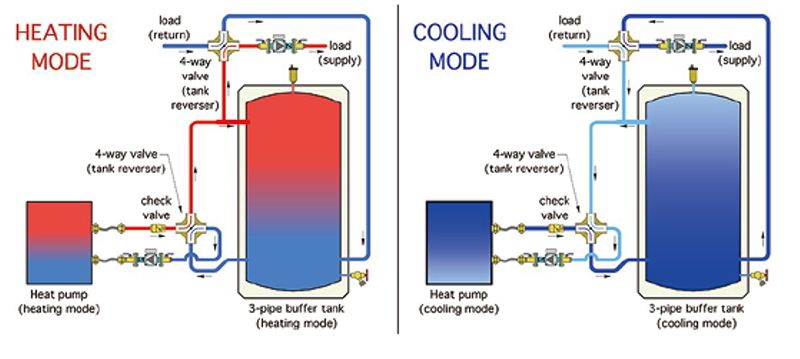

Pipe connections should be configured so that the buffer tank can act as both a thermal buffer and, if needed, a hydraulic separator between the heat source and the distribution system, which improves flow stability and reduces unnecessary stress on pumps.

All installations should comply with local plumbing and mechanical codes. This includes ensuring the system has appropriate pressure relief valves and expansion fittings , and that the tank is securely supported due to its weight when filled.

Proper piping layout is equally important: it helps avoid air locks, allows for correct temperature stratification inside the buffer tank, and ensures that the hottest water is available where and when it’s needed.

Although buffer tanks are generally low-maintenance, periodic attention helps ensure long service life and reliable performance. Key maintenance tasks include:

Periodic Inspection: At least once a year, inspect the tank and associated piping for signs of corrosion, leaks, or damage to insulation that could increase heat loss.

Pressure Relief Valves: Check the pressure relief valves regularly to ensure they are operating correctly and safely—this is vital for pressurized insulated tanks.

Sediment and Internal Cleaning: If the tank has internal heat exchangers or exposed surfaces, periodic flushing or cleaning may be needed to prevent scale buildup over time, especially in areas with hard water.

Insulation Integrity: Maintaining the quality of tank insulation preserves thermal efficiency and minimizes stand-by loss, which contributes directly to energy savings.

Most buffer tanks do not require frequent internal servicing, but checking heat source controls, circulation pumps, and sensor accuracy as part of routine heating system service helps identify issues early.

Heat Pumps (air-to-water, geothermal, etc.), which benefit greatly from added thermal mass to reduce short cycling.

Solar Thermal Collectors, where excess captured heat can be stored in the buffer tank and drawn on as needed.

Electric Heating Elements , which can be used as auxiliary heat within the buffer tank for backup or peak load support.

Gas or Oil Boilers particularly in hybrid systems where traditional combustion sources and renewable systems work together to meet demand.

By allowing multiple heat sources to contribute heat into a central storage tank, homeowners can optimize system efficiency, improve temperature control, and tailor operations based on energy cost or availability.