In modern building heating systems, a buffer tank is no longer an optional add-on—it is a critical component that significantly enhances the performance, reliability, and efficiency of heat pump installations. As enclosed, insulated vessels designed to store thermal energy, buffer tanks act as the heart of the system’s hydraulic and thermal balance , bridging the gap between heat generation and heat consumption. By storing excess heat and releasing it when needed, these tanks play an essential role in achieving stable system operation and improved energy utilization throughout the year.

At its core, a buffer tank serves as a thermal reservoir that absorbs surplus heat from the heat pump during periods of low demand and supplies that energy when demand increases. Without such storage, a heat pump would be required to cycle on and off frequently to meet fluctuating loads, a behavior known as short cycling . Short cycling not only reduces operational efficiency but also accelerates wear and tear on compressors and other system components. By decoupling generation from consumption, buffer tanks allow heat pumps to operate at more continuous, efficient load profiles, translating into higher seasonal performance and extended equipment lifespan.

A heat pump buffer tank is an insulated water storage unit integrated hydraulically between the heat pump and the heating distribution system. The water inside the tank functions as a medium for storing thermal energy. When the heat pump produces more heat than the current load requires, the excess thermal energy is transferred into the buffer tank. Conversely, during peak demand or when the heat pump is idle, the stored energy is drawn from the tank and fed into the heating circuits, such as underfloor heating or radiators.

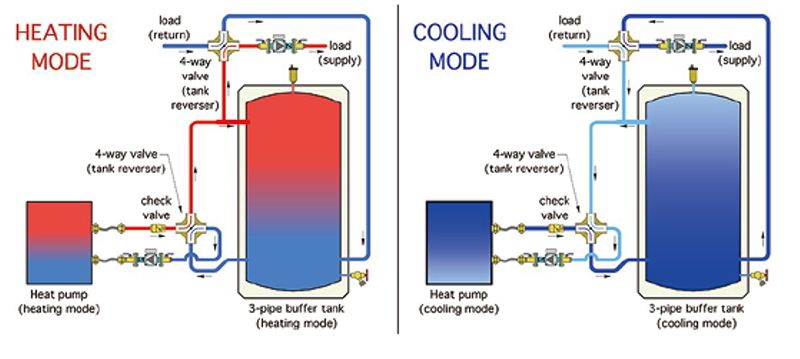

The hydraulic connection layout of buffer systems can vary based on design intent. In a series configuration , all water from the heat pump passes through the buffer tank before entering the heating circuits, effectively creating a common thermal mass that smooths temperature pulses and stabilizes return temperatures. In a parallel or branch configuration , the buffer tank selectively engages only when there are deviations in flow or thermal demand, acting more as a supplementary reservoir than a primary flow path. Each approach has advantages and trade-offs in terms of efficiency, mixing behavior, and control complexity.

Buffer tanks are not one-size-fits-all; they can be categorized based on their internal structure, hydraulic behavior, and integration flexibility:

Conventional buffer tanks are the simplest form, where incoming heat mixes with the stored water, achieving system temperature balance. These are well suited for smaller systems that do not require varying temperature levels or complex energy source integration.

Stratified buffer tanks take a more advanced approach. They maintain layered temperature zones within the tank, with hotter water at the top and cooler water at the bottom. This stratification allows multiple systems with different flow temperature requirements to operate more efficiently, as circuits can draw from the layer most closely matching their needs. While more expensive and requiring careful design, stratified tanks improve energy utilization and support the integration of diverse heating sources.

Bivalent buffer tanks expand on this concept by integrating two distinct heat sources—such as solar thermal collectors, electric heaters, or fossil fuel boilers—alongside the heat pump. These tanks provide flexibility and reliability in environments with varying external conditions, ensuring that thermal demands can be met even when renewable inputs are insufficient.

Integrated buffer tanks combine the heat pump and the storage vessel into a compact unit. This configuration minimizes installation space and reduces thermal losses but generally offers less flexibility for integrating additional energy sources or managing large heating systems.

The primary advantage of including a buffer tank in a heat pump system is the reduction of short cycling —a significant contributor to diminished seasonal efficiency. Frequent cycling not only reduces the average coefficient of performance (COP) of the heat pump but also increases mechanical wear, leading to higher maintenance costs and shorter service life. By providing a thermal buffer, the system operates more continuously within its optimal efficiency range.

Buffer tanks also play a vital role in hydraulic decoupling . They allow multiple heating circuits—such as domestic hot water, radiant floor systems, and radiator loops—to be supplied from a common storage source without interfering with each other’s flow requirements. This flexibility simplifies control strategies, improves comfort, and can reduce pump energy consumption by balancing flow rates across the system.

Another benefit lies in the integration of multiple heat sources . Solar thermal systems, district heating networks, or auxiliary boilers can be incorporated into the system through internal or external heat exchangers. The buffer tank becomes a central hub for thermal energy distribution, absorbing solar gains during the day and supplementing with heat pump input or other sources as needed. This hybrid approach maximizes renewable energy use while ensuring reliable performance under varying conditions.

The size of the buffer tank has a measurable impact on heat pump performance, especially in variable load scenarios. A larger tank increases the available thermal capacity, allowing longer uninterrupted run times and further reducing cycling. This leads to higher annual performance factors , as the heat pump spends more time operating efficiently and less time idling or switching on and off.

Proper integration considers not only volume but also hydraulic layout , flow temperatures, sensor positions, and control strategies. For complex or larger buildings, simulation tools can model dynamic load profiles and help optimize tank size, connection points, and energy source interactions. Such simulations can identify risks like excess cycling or mismatched flow requirements before installation, ensuring the system delivers both comfort and efficiency.

While buffer tanks are essential in larger systems, they provide value even in residential settings. In smaller homes, buffer tanks allow heat pumps to operate smoothly with underfloor heating or multi-zone radiators. In multi-family buildings, they help balance load between units and enable efficient energy sharing. Hotels and commercial buildings benefit from buffer storage by reducing peak loads and improving comfort consistency, while institutions such as hospitals or office buildings rely on stable thermal supply for critical operations.

Buffer tanks are also integral to hybrid renewable systems , where seasonal or intermittent energy sources like solar thermal require storage to match demand patterns. In these cases, the buffer tank ensures that solar thermal gains are captured and used effectively, even when direct demand is low.

In heat pump system design, a buffer tank is much more than a simple storage vessel. It is a strategic component that enhances system stability, efficiency, and flexibility. By managing thermal energy storage and distribution, buffer tanks reduce equipment stress, improve seasonal performance, and enable the integration of diverse heating resources. Whether for residential heating, hybrid energy systems, or complex multi-zone buildings, the inclusion of a buffer tank is a hallmark of thoughtful, efficient system design.